China Wholesale Free Fall Factories – LMEC-17 Uphill Roller Experiment (Energy conservation) – Labor

China Wholesale Free Fall Factories – LMEC-17 Uphill Roller Experiment (Energy conservation) – Labor Detail:

Experiments

1. Learn to use vernier caliper, screw micrometer and other related measurement;

2. The physical phenomenon of double cone rolling from low to high was observed from the surface and visual effect;

3. Master the law of conservation of mechanical energy, clear cone rolling is the principle of potential energy into kinetic energy

Total energy conservation;

4. Verify the experimental conditions of cone roll up; When the cone is designed and calculated to meet the condition of up rolling, the guide

The angle of the rail opening, the descent height of the rolling end relative to the end of the rail and the plane inclination of the cone rail are related to each other, then assemble and observe the experimental phenomena;

Main technical features

1. Miniaturization: the base area of the cone up rolling tester is only 32 × The length of guide rail is only 44cm

about;

2. Detachability: all links of the tester can be disassembled;

3. Strong three-dimensional adjustability: the angle between the two tracks of the cone can be adjusted, the inclination angle of the track plane can be adjusted, and the

Different sizes of cones (diameter and height) were selected for experiments;

4. Design experiment: according to the known parameters, the relevant parameters can be calculated by necessary calculation;

5. Comprehensive experiments: both qualitative and quantitative verification of cone rolling experimental conditions.

Main technical parameters

1. The parts of the instrument are made of stainless steel;

2. Base area 300 × 450mm, base thickness 9.00mm; 92 mm in diameter;

3. The radial distance between the upper surface of the crank and the connecting shaft of the crank and the support rod is 40.18mm

The diameter of rod connecting bearing screw is 4.60mm;

4. The diameter of fixing screw between bearing support rod and base is 31.60mm;

5. The diameter of the fixing screw between the supporting rod at the end of the double track and the base is 26.80mm;

6. On the premise of double guide rail leveling, the lower support rod of the bearing and the fixed screw of the base are connected to the support rod at the end of the track

The outer diameter distance between strut and base fixing screw is 395.00mm;

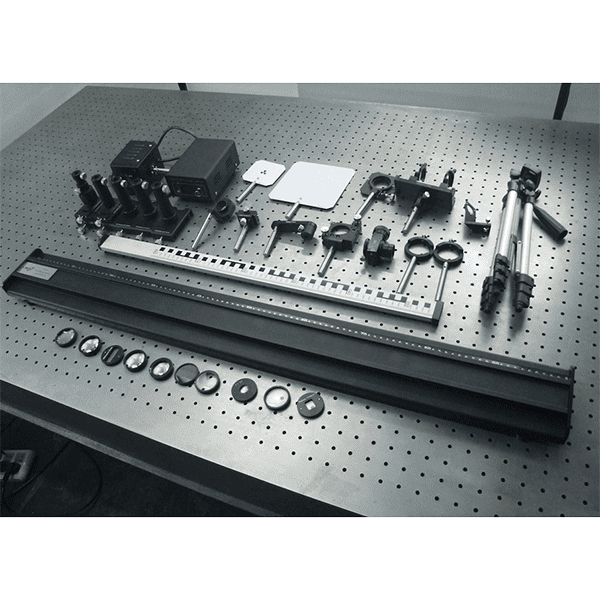

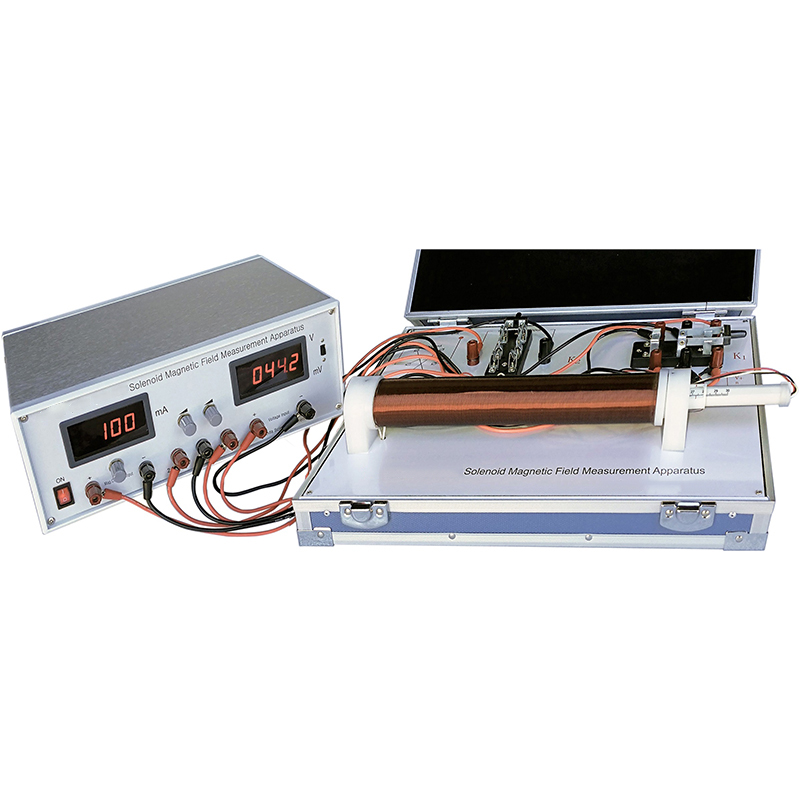

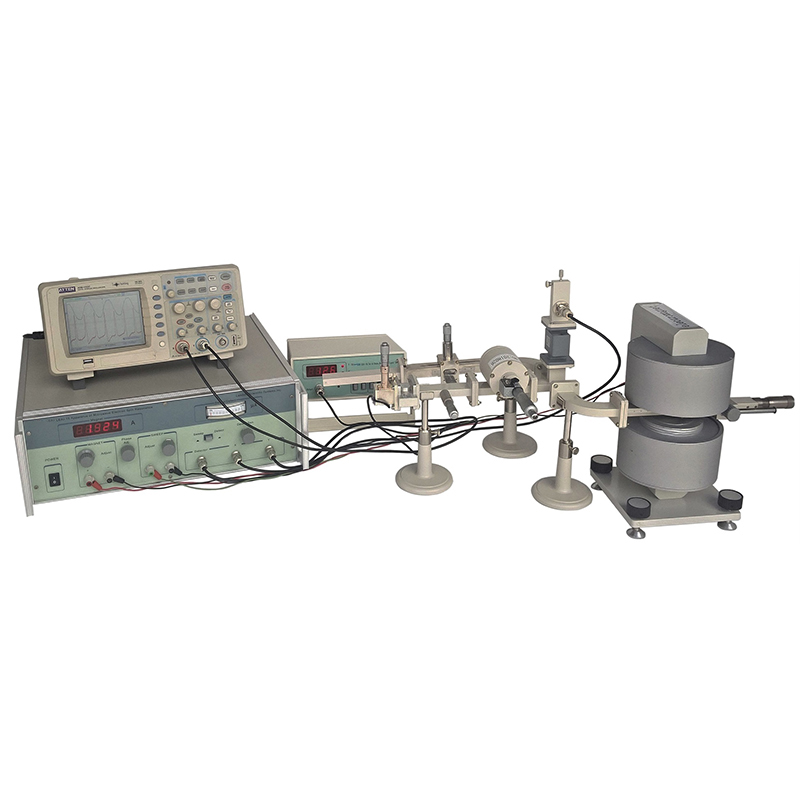

Product detail pictures:

Related Product Guide:

The business keeps to the operation concept "scientific management, premium quality and efficiency primacy, customer supreme for China Wholesale Free Fall Factories – LMEC-17 Uphill Roller Experiment (Energy conservation) – Labor , The product will supply to all over the world, such as: Estonia, Brisbane, Surabaya, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, make sure you kindly contact us, we have been looking forward to building up a great business relationship with you.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.